Let’s start with this photo from likely late 1915, which has been discussed on Gwulo lately. Besides the view of the just finished KCR Terminus building, it reveals a lot about road construction techniques in Hong Kong at the beginning of the 20th century.

History of road construction

In former times roads were more or less paths that were made by just leveling the natural ground. This worked quite well for pedestrians or pack animals. The use of carts and carriages was not so convenient on these roads, due to often bad conditions the traveling speed was pretty low. And rain, especially heavy rain as in typhoons, turned these roads into a mud bath making them almost impassable (see e.g. here). Later, especially for important roads in or between cities, a more elaborate construction technique was used with layers of thick stones as a base, and smaller gravel on top. This worked somewhat better, but was elaborate and costly.

In the 1820s, John McAdam (1756-1836) from Scotland developed a new method of road construction. He believed that the native soil alone would support the road and traffic upon, assuming that the surface of the road would be watertight to prevent water reaching the soil underneath. Rain water would run off into ditches on either side by cambering and elevation of the road above the water table. The road would be constructed starting with a 20 cm (8 in) thick bottom layer of stones with maximum top size of 7,5 cm (3 in), followed by a top layer of 5 cm (2 in) thickness made of stones with a maximum top size of 2 cm (0,79 in). A painting showing the construction of a road in 1823 can be viewed here . McAdam believed that carriages with their iron tyres would compact and level the road. This didn’t work properly, so iron-cast rollers were used for the compaction like this one:

This was the technique (named macadam) applied in the next decades, so in Hong Kong. When reading the Public Works Reports, we find many times “Forming, surfacing, kerbing and channelling” of a road. Next two examples of roads and the drainage systems built are shown below.

Road Works in front of the KCR Terminus

The Public Works Report for 1916 refers:

The area immediately in front of the station and to the south of Salisbury Road was made up to the required levels and macadamised, the necessary kerbing, channelling and footways being also provided.

Let’s go back to the first photo and look at some details.

In front of the pillars and the fence the footways are already finished, this gives almost the final level of the road. On the right the surface (with some dark patches) was leveled, probably it’s the upper level of the reclaimed land. Currently, a layer of stones is filled up in the centre of the photo. A worker is doing so, possibly using a wheelbarrow. On the left side, this first layer is completed already. For the transport of stones also baskets were used, carried using a yoke. Guessing from the thickness of the yoke, the top size of the stone might be around 7,5 cm as mentioned above. Near the footway, a wooden frame like a sledge with a handle is visible, possibly for leveling the surface. And, of course, an iron-cast roller is waiting for being used.

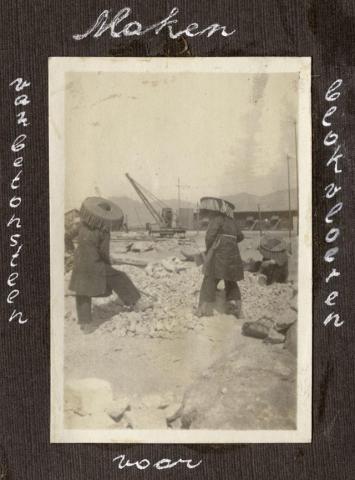

More workers are on this cut-out from the original photo:

Two of them carry stones in baskets using yokes, others spread stones with shovels or similar equipment.

And a third cut-out shows two men walking and some equipment on a (wooden?) podium.

On the left side, a bench is visible with a slanted seating – no idea, for what this is for.

Train Tracks

And now let’s talk about the rails.

Rails laid in streets have sleepers placed on a surface, in this case at the level (of the reclaimed land) we saw in the second cut-out. The thickness of sleepers plus rails must be the same as the final layers of stones (or surface) of the road. This can be seen here .Then stones (gravel) are put in between and on top of the sleepers until the final level is reached.

Again, the same two layers are used as for the road. In front of the terminus, twin rails are laid to make it easier for vehicles to cross.

This could be just two rails each laid parallel, or real twin-rails like these.

The twin rails don’t have the same length, this is to screw the next set of rails to the existing ones.

But why do the rails end halfway? The reason is given in the final cut-out:

These are the rickshaws queuing for passengers arriving at the Kowloon Star Ferry Pier. It certainly would be difficult to cross the rails. So I believe that further rail construction as well as the filling up with stones (macadamising) was done after finishing the final surface near the terminus, and rickshaws would queue and ride there.

Tar-macadam

Between the rails and some 10-20 cm left and right of them a dark colour is visible. It seems that the final layer of smaller stones of maximum top size of 2 cm is already put in place and was compacted.

Where does this dark colour come from?

Originally, the final layer would only be stones only, this was called water-bound macadam. That would not withstand heavier and especially faster traffic like cars. The rubber tyres of the cars would produce dust that wasn’t annoying only but also produced abrasive wear and lead to lane grooves.

In the minutes of a Hongkong Legislative Council Meeting on 2nd December, 1909 we learn about

A tar macadam factory used by the Public Works Department in the surfacing of Kennedy Road.

This is not yet equivalent to today’s asphalt cover, but it sealed the surface to prevent dust formation and enhanced water proofing.

So the dark colour likely comes from the tar, or actually tar oil sprayed (or just poured) on top of the stones. This can be seen here.

Availability of the tar caused no problems, it came from the Hong Kong gas works.

To have a smooth surface of the road, hand-operated cast-iron rollers were used for a long time, also breaking of stones often was done manually:

But improvement was near. The Public Works Report for 1898 refers:

Both these difficulties have been overcome by the purchase of a machine stone breaker and the ordering of a ten-ton steam road roller from England.

A stone breaker (today we would say rock crusher) from around 1900 manufactured in England is shown here (of course, in a museum), it was probably powered by a steam engine with a flat belt.

And the steam roller in Hong Kong is just coming around the corner.

Finish

And this is the final result of all of the construction work:

Note: The dark colour of the tar is gone, possibly granite rock flour was used as a finish because tar is a bit sticky, especially when it’s hot.