Current condition

Demolished / No longer exists

Date completed

Date closed / demolished

Completion date of 1898 from the Public Works Department's Annual Report for that year:

Demolition date of 1914 from a notice on 20th May 1914 in the Government Gazette that the company was entering liquidation.

Later place(s) at this location

Comments

cotton mills location

The location is St.Paul Convent Scjool & St. Paul's Hospital

Re: location

Location given is correct. Thus the lane Cotton Path.

Re: Location

Hi there,

I believe the former cotton mills took up the whole block back then, which included the present day residential blocks along Haven Street and Caroline Hill Road.

Best Regards,

T

Re: Location

Thanks for the extra information, I've set the marker to the right location. Good to see that the dates match up with the dates for the next occupants of the site.

Regards, David

http://books.google.com/books

http://books.google.com/books?id=t5gtAQAAMAAJ&dq=%22john%20grant%20smit…

http://books.google.com/books?id=t5gtAQAAMAAJ&pg=PA26&img=1&zoom=3&hl=e…

bitmap image. I have an old version of Paint so I cannot convert it and upload it to Gwulo.

The origin of the name Cotton Path

I think it is generally agreed that the name of Cotton Path was derived from the Cotton Mill. Recently a friend told me that the government did a cotton planting experiment there from 1904 to 1906, and she believes that it was the origin of the name of the path.

Just gone through the HKU gro and found information aout the "cotton planting," but it didn't mention where the cotton had been planted. (And it was a failed experiement too.)

Does anyone has an idea for it?

re: The origin of the name Cotton Path

It looks as though the name "Cotton Path" was introduced in 1931, see notice 436 in the Government Gazette for July 10, 1931:

http://sunzi.lib.hku.hk/hkgro/view/g1931/619131.pdf

It seems more likely the name would refer to the Cotton Mills, a large local landmark, than to a cotton planting experiment that happened 20+ years earlier.

I'm happy to be proved wrong though - can your friend tell us more about why she thinks it is named after the cotton planting?

Regards, David

In August 1897, considerable

In August 1897, considerable excitement in business circles was caused by the announcement that a cotton mill was to be established in Hongkong. In the weekly Share List Mr. Erich Georg wrote: " A local company has been formed for the erection of a Cotton Spinning Factory in this Colony, under the auspices of Messrs. Jardine Matheson and Co as general managers. The shares have all been underwritten, but I hear that a portion is likely to be offered to the general public. The site of the factory will be at East Point near the Sugar Refinery, where a sufficient water supply is obtainable

The Cotton Spinning Factory at East Point was opened in 1899 and was operated until late in 1910 or early in 1911 when it was closed down. As a business proposition it was a failure, the lack of skilled labour proving the greatest obstacle to its successful operation. The building was subsequently purchased by the French Sisters and the French Sisters Hospital now stands on the site of the old mill. The machinery was sold to Ewes and shipped to Shanghai in 1913.

Source: Old Hong Kong by Colonial Vol 1

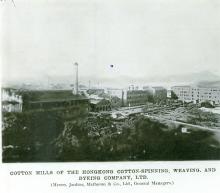

HONQKONG COTTON-SPINNING,…

HONQKONG COTTON-SPINNING, WEAVING, AND DYEING COMPANY, LTD.

COTTON-SPINNING in all its stages may be seen at the great factory at Causeway Ray, owned by the Hongkong Cotton-spinning, Weaving and Dyeing Company, Ltd., the general managers of which are Messrs. Jardine, Matheson & Co., Ltd. The buildings are nine in number and cover a very large area. The total space enclosed is 400,000 square feet, and the Company has sufficient ground to double the present plant should occasion arise. The size of the mills may be judged by the fact that there are over 55,500 spindles. The raw cotton comes principally from India, while China is the chief market for the manufactured article. The bales of cotton are broken open and their contents fed into the bale-breakers, which remove seed and other impurities from the cotton in readiness for the hopper feeding machines, in which a straightening-out process takes place. In the scutching department the cotton is freed from dirt, leaves, and other impurities by means of powerful fans, and as it issues from the scutching machines it is wound into what are known as laps. Four of these laps are placed on a second machine and made into one, with the object of ensuring uniformity of thickness. On the carding engine the cotton is combed out by large cylinders, covered with slightly projecting wire, and working to the thousandth part of an inch, while in the drawing frames the carded cotton is drawn out and the fibres are placed in a perfect parallel order. In the slubbing, intermediate, and roving frames the cotton is twisted, each process making the thread finer and at the same time stronger. The spinning and reeling frames complete the process, and the yarn is then wound into hanks and put up into bundles, which are stamped with the firm's chop — the dragon and the flag labels being the best known — and baled ready for export. There are 170 carding engines, 21 sets of drawing frames, 21 sets of slubbing frames, and 30 intermediate frames, to mention but some of the departments. The whole of the machinery is by Platts, of Oldham, and of the latest and most improved pattern known in the industries. It is perfect in its action, and adjusted with such nicety that even children may be entrusted with some of the operations.

From p.236 of Twentieth Century Impressions ...